Are you looking to improve the performance of your products? Look no further than customized cable assemblies! These specialized cables are designed to meet the specific needs of your product, improving its efficiency and reliability. In this blog post, we'll dive into what customized cable assemblies are, how they can benefit your product's performance, the different types available, and how to choose a supplier for them. Get ready to take your product's performance to new heights with customized cable assemblies!

What are Customized Cable Assemblies?

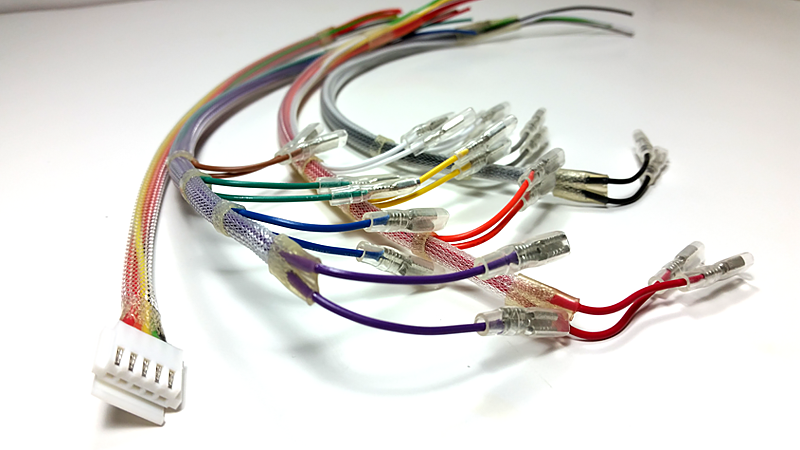

Customized cable assemblies are a type of cable that is specifically designed and manufactured to meet the unique needs of a particular application. They can be made from various types of cables, including coaxial, ribbon, or twisted pair cables, among others.

One advantage of customized cable assemblies is that they can be tailored to meet specific requirements such as length, gauge size, connector style or material type. This ensures optimal performance in terms of signal transmission and electrical conductivity.

These specialized cables are often used in industries such as aerospace, medical devices and telecommunications where reliability and performance are crucial. For example, in medical equipment applications where precision is critical for accurate measurements; customized cable assemblies offer high levels of accuracy due to their design.

Customized cable assemblies offer significant advantages over off-the-shelf-cables by providing superior durability and efficiency while also saving time during installation due to being preassembled with connectors.

How do Customized Cable Assemblies Improve Product Performance?

Customized cable assemblies play a critical role in improving product performance. These assemblies are designed to meet the specific needs of a particular application, ensuring that the cables fit perfectly and work optimally. Here are some ways customized cable assemblies can improve your product performance:

Firstly, customized cable assemblies ensure that only the necessary components are included in the design, which leads to more efficient operation and reduced costs. This means you won't have extra wires or connectors cluttering up space in your equipment.

Secondly, by eliminating unnecessary components and customizing the assembly according to specific requirements, it's possible to reduce signal loss and noise interference significantly. As a result, your system will operate more smoothly with fewer errors or disruptions.

When using customized cable assemblies that have been built specifically for an application’s unique requirements, it is easier for manufacturers to maintain quality control standards throughout production. This helps prevent any defects from entering into finished products as well as reducing potential maintenance issues down the line.

If you want high-quality performance from your products while minimizing downtime due to wiring-related issues or component failures then consider opting for customized cable solutions tailored around your specific needs!

Types of Customized Cable Assemblies

Customized cable assemblies come in various types, each designed to meet specific requirements of a product. The type of customized cable assembly used will depend on the application and environment. Here are some common types of customized cable assemblies:

1. Coaxial Cable Assemblies: These are used for high-frequency applications such as radio communication and video transmission.

2. Flat Ribbon Cable Assemblies: They are commonly used for connecting electronic devices where space is limited.

3. Power Cables: These cables have large diameter conductors, suitable for transmitting high levels of power without overheating or short-circuiting.

4. Control Cables: Used for automation and control systems, these cables incorporate multiple cores within a single jacket to provide flexibility in routing and installation.

5. Data Cables: Designed specifically for data transfer between devices or networks, these cables can transmit data at very high speeds with minimal interference.

6. Custom Hybrid Cables: Some applications require unique combinations of different cable types into one assembly, which can be achieved through hybrid customization.

Choosing the right type of customized cable assembly depends on several factors such as voltage ratings, signal frequency range, environmental conditions like temperature extremes or exposure to chemicals/moisture/dust etc., required mechanical properties like flexibility/rigidity/strain relief features etc.. Working closely with an experienced supplier can help ensure that you get the right custom solution that meets your exact product needs!

Why Use a Customized Cable Assembly Supplier?

When it comes to designing and manufacturing products that require cable assemblies, using a customized cable assembly supplier can make all the difference. Customized cable assemblies are designed specifically for your product's unique needs, ensuring optimal performance, reliability and durability.

Using a customized cable assembly supplier means you have access to experienced professionals who understand the intricacies of cable assemblies. They will work with you every step of the way, from design to production, to ensure that your product is equipped with high-quality cables tailored specifically for its requirements.

A good customized cable assembly supplier will also offer a wide range of customization options such as length, color-coding and labeling. Being able to customize these features ensures that each component fits perfectly into your product's specifications.

Another advantage of using a specialized supplier is their ability to source materials at competitive prices without sacrificing quality. This helps minimize project costs while maintaining excellent standards in terms of functionality and longevity.

By partnering with a reliable custom cable assembly manufacturer, you'll gain peace of mind knowing that your products are assembled by experts utilizing advanced technology processes backed up by stringent quality control measures. Overall this translates into enhanced satisfaction among customers leading ultimately towards higher customer retention rates.

How to Choose a Customized Cable Assembly Supplier

When it comes to choosing a customized cable assembly supplier, there are several factors that you need to consider. First and foremost, you need to look for a supplier who has experience in the industry. Experience is important because it means that the supplier will have knowledge of different types of cable assemblies and can offer valuable suggestions based on your specific needs.

Another factor to consider is whether the supplier can provide custom solutions that meet your exact requirements. You should also check whether they use high-quality materials and components in their products, as this will directly impact the performance of your product.

It's important to choose a supplier who values communication and collaboration with their clients. This ensures that any issues or concerns can be addressed quickly and efficiently, ultimately saving time and money.

Additionally, take into consideration the lead times offered by potential suppliers - do they match up with your production schedule? Will they be able to accommodate any changes or revisions along the way?

Don't forget about pricing - while cost shouldn't be the only deciding factor when choosing a customized cable assembly supplier, it's still an important consideration. Look for a balance between quality products/services and fair pricing.

By taking these factors into account when selecting a customized cable assembly supplier,you'll increase your chances of finding one who meets all of your unique needs.

Conclusion

Customized cable assemblies are an essential component that can significantly improve your product's performance. With the right custom assembly, you can ensure the reliability and durability of your products while enhancing their functionality.

Customized cables come in different types and are designed to meet specific needs and requirements. Working with a reputable supplier will help you get quality materials, guarantee proper installation, reduce downtime, and minimize repair costs.

Therefore, it's crucial to choose a reliable custom cable manufacturer who understands your unique needs. By choosing the right manufacturer for your customized assembly needs, you'll have peace of mind knowing that your products will perform optimally under any condition or application.

icons at the top right corner of the subsection.

icons at the top right corner of the subsection.