Selecting

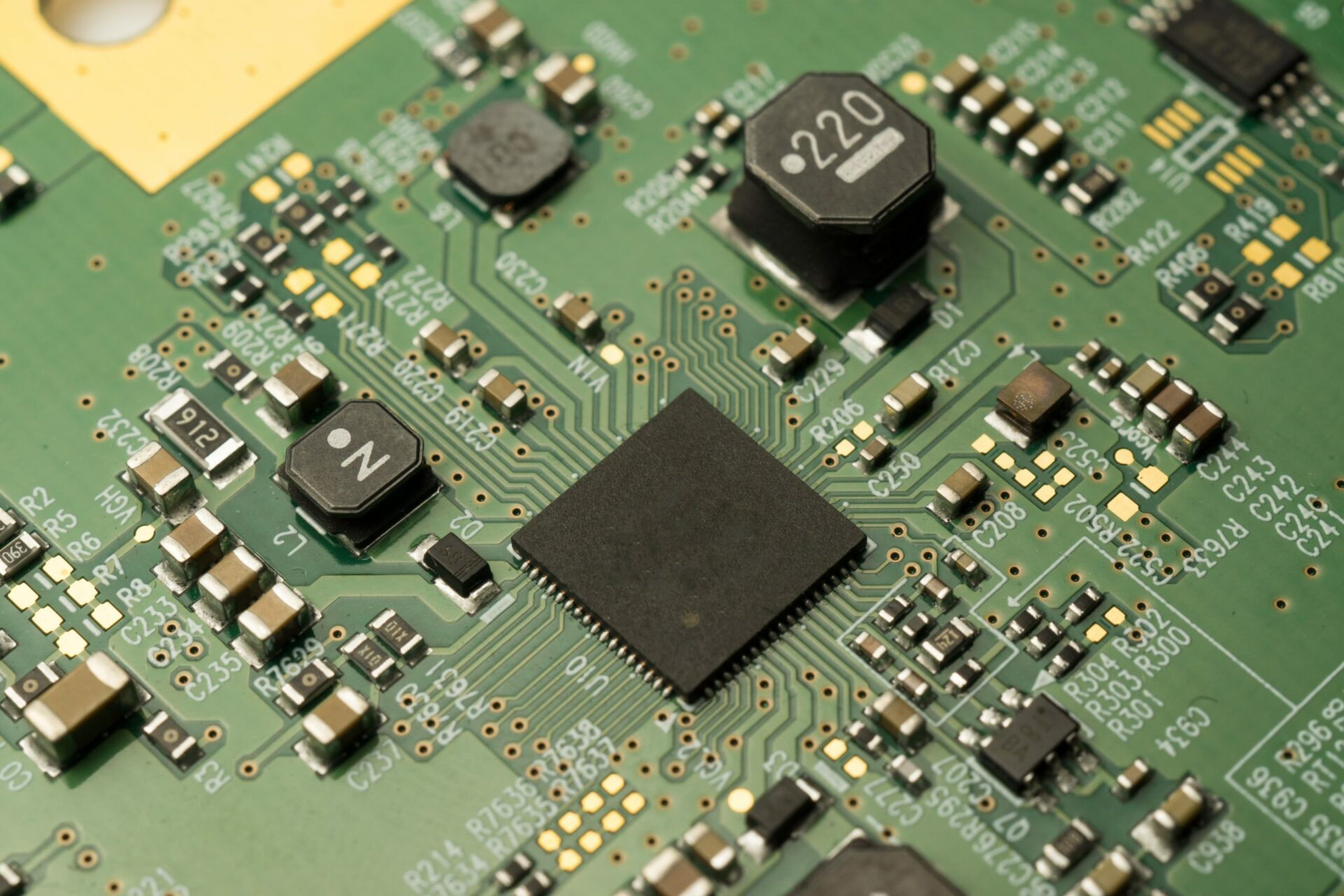

web link Printed Circuit Board (PCB) supplier or assembly service is a crucial choice that can substantially impact the success of your digital project. The quality, expense, and reliability of the PCBs are directly influenced by the capabilities and expertise of the producer. This article offers a thorough guide on how to pick a PCB maker or assembly service that best suits your requirements.

Understanding Your Needs

Before starting your look for a PCB manufacturer, it's essential to clearly understand your project demands. Think about the following:

PCB Technology: Figure out whether you require through-hole, surface-mount, or a combination of both technologies.

Board Dimension and Complexity: Examine the size and complexity of your PCB layout.

Quantity Requirements: Take into consideration whether you require a small set for prototyping or large manufacturing.

Preparation: Establish your timeline for prototype growth and final production.

Evaluating Experience and Online Reputation

The experience and reputation of a PCB supplier are important indicators of their capability to provide high quality items.

Market Experience: Seek manufacturers with a proven record in your certain sector.

Customer Testimonials: Look for consumer testimonials and testimonials to determine their reliability and solution top quality.

High Quality Specifications and Certifications

High quality needs to be a leading priority when choosing a PCB producer.

Qualifications: Ensure the manufacturer has relevant sector qualifications, such as ISO 9001 or IPC-A-610.

Quality Control Processes: Inquire about their quality control procedures, consisting of screening procedures and flaw monitoring.

Manufacturing Capabilities

The supplier's abilities need to straighten with your job demands.

Technology and Tools: Confirm if they have the current technology and equipment to produce PCBs that satisfy your requirements.

Prototyping Services: Inspect if they provide quick prototyping services, which are crucial for testing and validating your layout.

Expense Considerations

While cost is an important element, it must not be the sole standard for choice.

Affordable Prices: Demand quotes from several suppliers to contrast prices.

Hidden Costs: Recognize any type of added costs, such as tooling, screening, or shipping charges.

Consumer Support and Communication

Efficient communication and client assistance are important for a successful collaboration.

Responsiveness: Select a manufacturer that is receptive and connects plainly throughout the procedure.

Technical Support: Ensure they offer robust technical assistance and agree to team up closely on your project.

Lead Times and Versatility

Timely distribution is crucial, particularly if you have rigorous target dates.

Production Lead Times: Ask about their typical lead times for both prototyping and automation.

Adaptability: Examine their ability to suit urgent orders or modifications in your needs.

Supply Chain Administration

A trusted supply chain is vital to ensure the schedule of parts and materials.

Part Sourcing: Inquire about their part sourcing approaches and partnerships with providers.

Supply Monitoring: Examine if they have reliable stock management systems to deal with component lacks or delays.

Environmental Conformity

Make sure the supplier follows ecological regulations and practices.

RoHS Conformity: Confirm if they follow RoHS (Restriction of Hazardous Compounds) regulations.

Green Practices: Think about producers who implement environment-friendly practices in their manufacturing procedures.

Lasting Partnership Potential

Think about the possibility for a long-term collaboration with the manufacturer.

Scalability: Examine if they can scale production as your service grows.

Continuous Improvement: Look for makers who purchase constant enhancement and technological improvements.

Conclusion

Selecting the best PCB manufacturer or assembly service needs cautious factor to consider of different aspects, consisting of top quality, experience, capabilities, expense, and interaction. By extensively assessing potential companions versus these standards, you can make sure a successful collaboration that satisfies your task's needs and contributes to its general success. Keep in mind, the cheapest option is not constantly the very best; prioritize top quality and dependability to accomplish the most effective results for your PCB projects.

icons at the top right corner of the subsection.

icons at the top right corner of the subsection.