Introduction

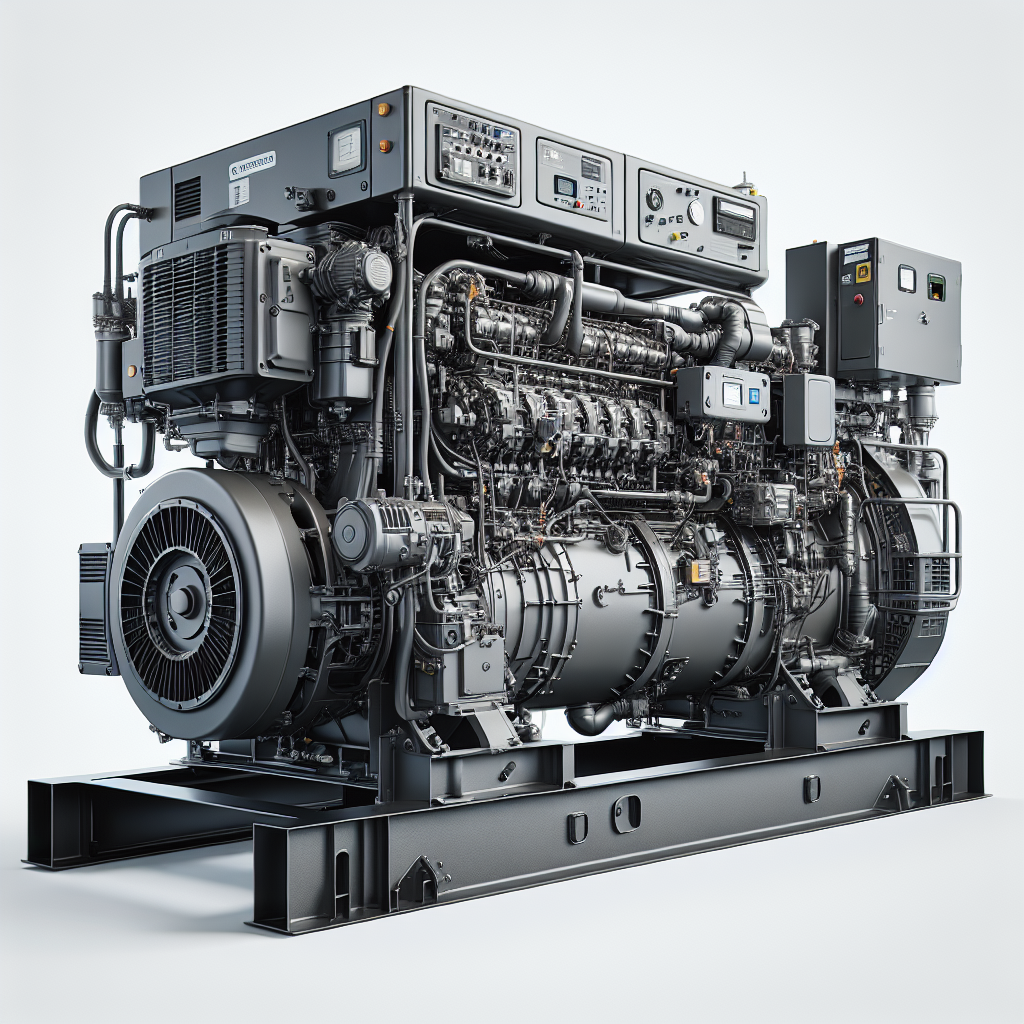

In industries and applications where corrosive atmospheres are prevalent, ensuring a reliable power supply is crucial for operational efficiency and safety. Diesel generators have long been a go-to solution for providing backup power in such environments due to their robustness and reliability. This article explores the challenges posed by corrosive atmospheres, the importance of reliable power supply, and the features and considerations to keep in mind when selecting diesel generators for use in such conditions.

Understanding Corrosive Atmospheres

Corrosive atmospheres are environments where there is a high presence of corrosive agents such as acids, salts, moisture, and other chemicals. These atmospheres can be found in a wide range of industries, including chemical processing plants, marine environments, wastewater treatment facilities, and coastal regions exposed to saltwater spray. The presence of corrosive elements can accelerate the deterioration of equipment and machinery, leading to premature failure and costly downtime.

The Impact of Corrosive Atmospheres on Power Generation Equipment

Diesel generators, like any other machinery, are susceptible to the damaging effects of corrosive atmospheres. The corrosive agents present in the environment can gradually corrode the generator components, leading to reduced performance, increased maintenance requirements, and ultimately, failure. Inadequate protection against corrosion can compromise the integrity of critical parts such as the engine, alternator, fuel system, and control panel, jeopardizing the overall reliability of the generator.

Importance of Reliable Power Supply in Corrosive Environments

In industries where corrosive atmospheres are prevalent, maintaining a reliable power supply is of utmost importance. Power outages can have severe consequences, including production downtime, equipment damage, safety risks, and financial losses. Diesel generators serve as a crucial backup power source, ensuring uninterrupted operation even in the face of utility power failures. Reliability is key when it comes to backup power systems, especially in corrosive environments where equipment degradation occurs at an accelerated pace.

Key Features of Diesel Generators for Corrosive Atmospheres

When selecting a diesel generator for use in corrosive atmospheres, several key features and considerations should be taken into account to ensure optimal performance and longevity. Some of the essential features to look for in diesel generators designed for corrosive environments include:

1. Corrosion-Resistant Materials: Diesel generators intended for use in corrosive atmospheres should be constructed from high-quality, corrosion-resistant materials that can withstand exposure to harsh chemicals and moisture. Stainless steel, marine-grade aluminum, and corrosion-resistant coatings are commonly used to protect critical components from corrosion.

2. Enclosure Design: The enclosure of the diesel generator plays a vital role in protecting the internal components from corrosive agents. Enclosures should be designed to prevent the ingress of moisture, dust, and corrosive particles while allowing for proper ventilation to dissipate heat effectively.

3. Sealed Electrical Components: Electrical components such as wiring, connectors, and control panels should be sealed to prevent corrosion-induced electrical faults. Sealed connectors and enclosures with gaskets can help maintain the integrity of the electrical system in corrosive environments.

4. Coating and Finishing: External surfaces of the diesel generator should be treated with corrosion-resistant coatings or finishes to provide an additional layer of protection against corrosive elements. Powder coating, galvanizing, and specialized coatings designed for corrosive environments can help prolong the lifespan of the generator.

5. Maintenance-Friendly Design: Diesel generators for corrosive atmospheres should be designed for ease of maintenance and serviceability. Access panels, removable covers, and clear service points facilitate routine inspections and maintenance tasks, allowing for timely identification and mitigation of corrosion-related issues.

6. Ventilation System: Proper ventilation is essential for dissipating heat generated during operation and preventing the buildup of corrosive gases inside the generator enclosure. Ventilation systems should be designed to maintain a constant airflow while filtering out contaminants that could accelerate corrosion.

Considerations for Selecting Diesel Generators for Corrosive Environments

In addition to the key features mentioned above, there are several important considerations to keep in mind when selecting diesel generators for corrosive atmospheres:

1. Environmental Conditions: Understand the specific corrosive agents present in the environment where the generator will be installed. Factors such as humidity levels, temperature fluctuations, exposure to saltwater, and chemical concentrations will influence the type of corrosion protection required.

2.

75kw diesel generator : Determine the power output requirements of the application to select a diesel generator with the appropriate capacity and load handling capabilities. Oversizing or undersizing the generator can lead to inefficiencies and premature wear in corrosive environments.

3. Compliance with Standards: Ensure that the diesel generator meets relevant industry standards and certifications for corrosion resistance, electrical safety, and environmental protection. Compliance with standards such as NEMA, IEC, and ISO can provide assurance of the generator's quality and suitability for use in corrosive atmospheres.

4. Warranty and Support: Choose a reputable manufacturer or supplier that offers comprehensive warranties, technical support, and maintenance services for the diesel generator. A reliable support network is essential for addressing any issues that may arise during the generator's lifespan.

Case Studies and Success Stories

Several industries have successfully implemented diesel generators in corrosive environments to ensure a reliable power supply and mitigate the risks associated with power outages. Case studies and success stories highlighting the effectiveness of diesel generators in challenging conditions can provide valuable insights into their performance and durability.

Conclusion

Diesel generators play a critical role in providing backup power in corrosive atmospheres, where maintaining a reliable power supply is essential for operational continuity. By selecting diesel generators with corrosion-resistant materials, robust enclosure designs, sealed electrical components, and proper ventilation systems, industries can ensure the longevity and performance of their backup power systems in challenging environments. Understanding the impact of corrosive atmospheres on power generation equipment and considering key features and considerations when selecting diesel generators are essential steps towards safeguarding against downtime and equipment failure in corrosive environments.

icons at the top right corner of the subsection.

icons at the top right corner of the subsection.