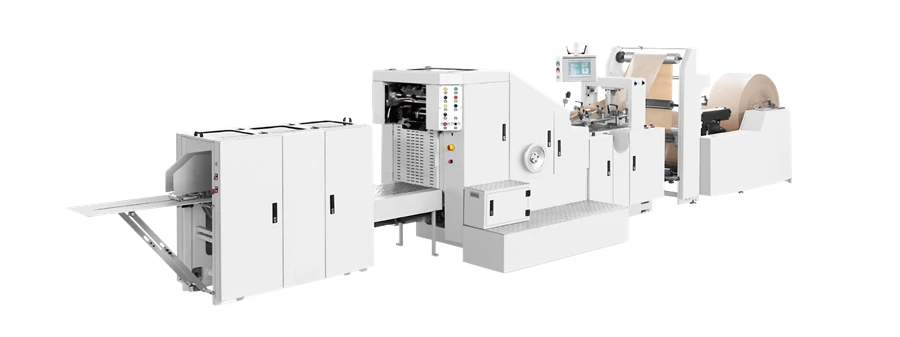

In the current fast-paced world, companies across various industries are recognizing that high-quality packaging is essential to their prosperity. jiandajx packaging machinery is at the forefront of this evolution, allowing companies to boost their efficiency, reduce waste, and offer superior products to their customers. A tailored packaging machinery manufacturer plays a critical role in designing tailored solutions that fulfill the unique needs of each industry, from agriculture and beverages to healthcare and beyond.

Investing in state-of-the-art packaging technology not only optimizes production processes but furthermore fosters sustainability and innovation. As organizations strive to differentiate themselves in competitive environments, the requirement for customized machinery that can adapt to specific product requirements and production environments keeps to expand. Understanding how packaging machinery manufacturing packaging machinery manufacturer can deliver solutions that align with these goals is crucial for companies looking to succeed in the future.

Advantages of Tailored Packaging Machinery

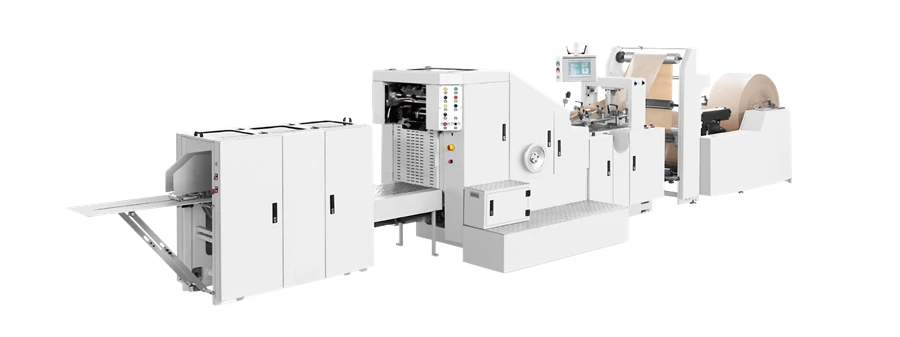

Bespoke packaging machinery offers significant advantages for businesses looking to enhance their production efficiency. One of the primary advantages is the ability to tailor the machinery to specific product requirements. This personalization ensures that the packaging process matches seamlessly with the sizes, weight, and style of the products being packaged. As a result, businesses can realize higher production rates and reduce the time and labor involved in packaging operations.

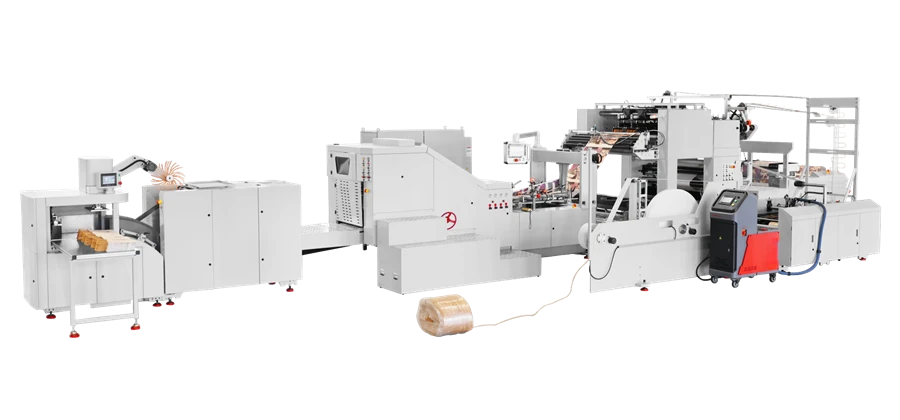

Another key benefit of bespoke packaging machinery is enhanced flexibility. As market demands and consumer preferences change, businesses often need to adjust their packaging solutions. Custom machinery can be designed to handle various packaging styles and materials, allowing companies to pivot quickly and efficiently. This adaptability not only helps businesses remain viable but also reduces downtime associated with equipment changes.

Lastly, allocating resources in tailored packaging machinery can lead to substantial cost savings in the future. By streamlining the packaging process and reducing material waste, companies can decrease their operational costs. Additionally, tailored packaging machinery manufacturing incorporates sophisticated technology that enhances accuracy and reduces the likelihood of mistakes, leading to fewer product returns and higher customer satisfaction. This investment ultimately positions businesses for sustainable growth and profitability.

Industry-Specific Strategies

Custom packaging machinery offers tailored solutions to meet the diverse needs of various industries, ensuring that products are sealed efficiently and effectively. In the F&B sector, for instance, machinery is designed to accommodate specific regulations regarding sanitation and product longevity. This includes equipment for vacuum packaging, liquid packaging, and branding that not only enhances product shelf life but also appeals to the consumer with appealing packaging.

The medicinal industry requires extremely specific machinery that ensures accuracy and compliance with rigorous safety standards. Bespoke packaging solutions are developed to handle various forms of medication, whether in aqueous, granule, or pill form. This includes safety packaging options and sealed pack machines that can safely seal products while maintaining purity. Such care is essential in ensuring the security and functionality of pharmaceutical products.

In the beauty industry, branding plays a crucial role. Bespoke packaging machinery allows for unique designs that highlight the aesthetic qualities of the product while ensuring functionality. From airless pumps for creams to advanced labeling systems for bottles, manufacturers provide solutions that not only protect the product but also enhance its consumer attraction. This adaptation helps brands differentiate themselves in a challenging marketplace while providing convenience to consumers.

Future Trends in Packaging Technology

The future of packaging tech is set for significant advancements, propelled by the increasing demand for effectiveness and sustainability across multiple industries. Custom packaging equipment manufacturers are at the forefront of this evolution, focusing on automation and digitization to enhance production processes. With the integration of smart technology, container processes will become more versatile, enabling for real-time data evaluation and modifications that refine operations and minimize loss.

Eco-friendliness is another key trend shaping the prospects of packaging technology. As customers become more environmentally aware, manufacturers are exploring sustainable materials and production techniques. Tailored packaging equipment will increasingly be created to utilize decomposable resources, minimize energy consumption, and promote recyclability. This shift not only meets compliance requirements but also corresponds with customer demands, driving product loyalty and market competitiveness.

Lastly, the growth of e-commerce is transforming packaging requirements across industries. Tailored container machinery must adapt to accommodate a broader range of product shapes and sizes while ensuring protection during transit. This flexibility will be essential for businesses looking to thrive in a quickly evolving retail landscape. Innovations such as customized container solutions and cutting-edge robotics are anticipated to gain momentum, enabling manufacturers to react quickly to consumer demands while upholding high-quality criteria.

icons at the top right corner of the subsection.

icons at the top right corner of the subsection.